We don’t tend to give keyboards a second thought here in 2016. They are ubiquitous and cheap. You can get a brand new one for as little as $5.00.

Not so in 1973. Keyboards in 1973 were up there cost wise. Home computing was virtually non existent. If you were a computing enthusiast or hobbyist, you faced a pretty steep bill for a new keyboard. You could, of course, pick up a surplus unit. These were discarded keyboards, typically from card punch machines. But there was a problem — these typically used old teletype or punch card coding standards like Baudot or EBCDIC. With ASCII taking over, you had your work cut out for you if you wanted to convert to this relatively recent standard.

Enter Don Lancaster.

Don preached electronics on the cheap from the pulpit of hobbyist magazines like Radio Electronics, and in February of 1973 he published an article in that magazine describing a cost effective, if tedious, means of building one’s own keyboard.

I don’t know how much of a hit the keyboard project was. It was a serious job, including hand winding springs and precise measurements and drilling of components. Having built the beast though, to make it truly useful one needed an encoder. And that was Don’s next project, in April of that same year.

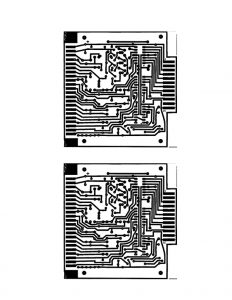

The device itself was about four inches by four inches, and was intended to bolt onto the Low Cost Keyboard. Don would ultimately improve on this design later on with emphasis on reducing size and complexity. But for my purposes, this is the encoder he used with his first TVT, and that’s what we’re going to build.

Since I have no experience building electronics from the ground up, I figured the encoder was a good starter project. The TVT itself involves much more complicated circuitry and a power supply, which is kind of intimidating. I need to get comfortable and learn on something I can afford to accidentally destroy, with minimal risk of death. This I can build and hook up to a bench power supply and hopefully just test with a logic probe. Plus, it’s going to be really cool resurrecting a project that was conceived 2 years before I joined this world.

Essentially the goal with an ASCII encoder is to be able to press a key and have it generate a 7 or 8 bit code that corresponds to the letter, number or function assigned under the ASCII standard. A code table is in the bottom left of this page from the article:

Your keyboard keys are arranged in a matrix. When you press a given key, it causes certain logic gates on the encoder to operate and enables or disables certain bits, from 1 to 7. If for example we press the P key, the encoder will cause bits 5 and 7 to go high (a logical 1) while all others remain low (a logical 0). The resulting code – 101-0000 is passed from the encoder to whatever device you have connected, and based on the ASCII standard that device knows to generate a P.

In a modern keyboard, all of this work is typically done by a single IC. But in 1973 such ICs weren’t widely available, so Don’s design was what he called ‘brute force’, using fairly basic logic and 3 Motorola hex inverter ICs to set the individual bits. The encoder required a 10V, 25ma power supply but this could be modified to 12 or even 5 volts by changing one of the diodes.

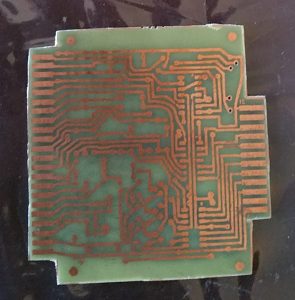

You’ll recall I etched this board already as part of my first run of TVT boards. To do this I simply lifted the artwork from a PDF of the article, flipped it, cleaned it up, printed it on magazine paper and then ironed it onto the board. My vinegar/peroxide etchant made quick work of this little board.

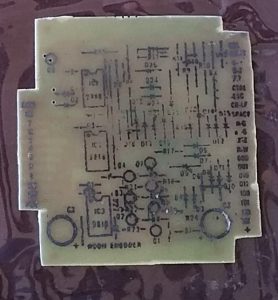

Apparently a few of these were available commercially, at least according to the article. It doesn’t look like they had any silkscreening for parts placement, but I decided to keep it easy by printing off the parts placement and transferring it to the non-copper side of the board once it was etched.

Assembling the required parts was not hard. In fact, I just did a few ebay purchases and within a couple of weeks had all the resistors and bits I needed. I even found NOS 1972 vintage Motorola MC9818P ICs!

That said, once I had it all in front of me I realized I wasn’t too happy with the resistors and electrolytic capacitors on offer. They look too modern! And small! The 100uf 10v caps on Don’s original were fairly big metal can type caps. Today’s equivalents are about 1/2 to 1/3 the size. I installed them anyway for now — they’ll work for testing purposes. The old metal can style seem to be unavailable anywhere at the moment. You can see in the upper right corner just how small it is compared to the footprint the ‘silkscreen’ expects it to be.

I also used one of my modern, Chinese made, carbon film resistors. I didn’t like it. It looks too modern. I think I’ll do some more research and see if I can hunt down some ‘correct’ vintage resistors.

Getting those first few parts installed though really changes things. This is going from a dusty historical footnote to a living, breathing device!

Greetings! Very useful advice within this article!

It is the little changes that will make the biggest changes.

Thanks a lot for sharing!

I could not resist commenting. Well written!

Magnificent goods from you, man. I’ve understand your stuff prior to and you’re just extremely excellent.

I actually like what you’ve bought right here, certainly like

what you are stating and the way in which in which

you say it. You’re making it entertaining and you continue to care for to stay

it smart. I can’t wait to learn far more from you. This is actually a great website.